Buying beach bags wholesale involves more than finding a supplier and placing an order. The process from initial research to receiving inventory typically spans 10-16 weeks and includes multiple decision points that impact your product quality, costs, and timeline. This guide walks through each step based on our 24 years of experience working with B2B buyers worldwide.

Executive Summary

- Total timeline: 10-16 weeks from first inquiry to receiving goods

- Key steps: Requirements → Supplier research → Samples → Negotiation → Production → Inspection → Shipping

- Standard payment: 30% deposit, 70% before shipping (T/T)

- Quality control: Pre-shipment inspection using AQL sampling is standard practice

- Cost factors: Unit price + shipping + customs = landed cost (plan for 20-30% above FOB)

Step 1: Define Your Requirements

Clear requirements prevent wasted time and miscommunication. Before contacting suppliers, document these specifics:

Product Requirements

- Material: Canvas, mesh, straw, polyester, jute

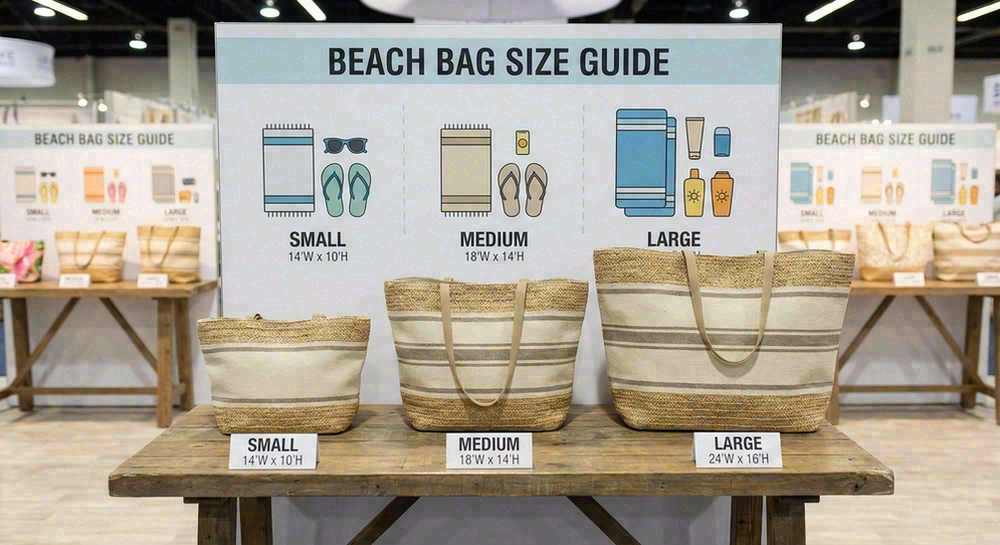

- Size range: Small, medium, large, or specific dimensions

- Style: Tote, drawstring, backpack, structured

- Features: Pockets, closures, waterproofing, reinforcement

- Customization: Logo printing, embroidery, custom colors

Business Requirements

- Quantity: First order volume and annual projected volume

- Budget: Target landed cost per unit

- Timeline: When you need goods in hand

- Certifications: BSCI, ISO, OEKO-TEX requirements

- Destination: Shipping location for freight quotes

Pro Tip: Suppliers respond better to specific inquiries. "I need 1,000 canvas beach bags, 18x14 inches, with one-color screen print, delivered to Los Angeles by June" gets faster, more accurate responses than "I'm looking for beach bags."

Step 2: Research and Shortlist Suppliers

Cast a wide net initially, then narrow systematically:

Finding Suppliers

- B2B platforms: Alibaba, Made-in-China, Global Sources

- Trade shows: Canton Fair, Magic, ASD Market Week

- Industry referrals: Non-competing businesses, trade associations

- Direct search: Google for manufacturers in production regions

Initial Screening Criteria

- Product match: Do they specialize in your product type?

- Capacity: Can they handle your volume?

- Experience: How long in business? Export experience?

- Communication: Response quality and speed

- Certifications: Relevant industry certifications

Red Flags to Watch

- Prices significantly below market (quality or ethics concerns)

- Vague about factory location or capabilities

- Resistant to factory visits or video calls

- No product specialization (trading company sign)

- Pressure for immediate large deposits

Target outcome: Shortlist of 3-5 potential suppliers for sample requests

Step 3: Request and Evaluate Samples

Samples reveal quality differences that photos cannot show. This step is essential.

Sample Request Process

- Request product catalog or available samples list

- Select 2-3 items representing your needs

- Clarify sample costs and shipping charges

- Provide shipping address and preferred carrier

Sample Cost Expectations

- Stock samples: Often free or at production cost ($5-$15 per item)

- Custom samples: $50-$200 depending on complexity

- Shipping: Buyer typically pays ($30-$80 express international)

- Refund policy: Many suppliers refund sample costs on order

Sample Evaluation Checklist

- Construction: Stitching quality, seam strength, handle attachment

- Materials: Fabric weight, texture, color consistency

- Hardware: Zipper function, snap strength, grommet quality

- Dimensions: Match specifications provided

- Finishing: Edge quality, lining alignment, overall cleanliness

Key Insight: Compare samples side-by-side from different suppliers. Quality differences become obvious when you can physically compare materials, construction, and finishing. The extra sample cost is insignificant compared to the cost of choosing the wrong supplier.

Step 4: Negotiate Terms

Negotiation covers more than price. Understanding standard terms helps you negotiate effectively:

Price Negotiation

- Volume leverage: Higher quantities = lower per-unit cost

- Annual commitment: Projected annual volume can unlock better pricing

- Simplification: Fewer colors, features, or customization reduces cost

- Reasonable targets: 5-15% below initial quote is typical; 30%+ requests signal unrealistic expectations

Standard Payment Terms

| Term | Structure | When Used |

|---|---|---|

| 30/70 T/T | 30% deposit, 70% before shipping | Standard for established relationships |

| 50/50 T/T | 50% deposit, 50% before shipping | New relationships, custom orders |

| L/C | Letter of Credit | Large orders ($50,000+) |

Other Negotiation Points

- MOQ flexibility: First orders may accept lower MOQ at higher price

- Lead time: Rush fees vs. standard timeline

- Shipping terms: FOB, CIF, DDP options

- Quality standards: AQL levels, inspection rights

- Defect handling: Replacement or credit terms

Step 5: Place Order and Manage Production

Once terms are agreed, formalize the order:

Order Documentation

- Proforma invoice: Details all specifications, quantities, pricing, terms

- Purchase order: Your formal order confirmation

- Technical specifications: Detailed requirements with measurements, colors, materials

- Approved sample: Reference sample for production matching

Production Milestones

- Deposit payment: Triggers production scheduling

- Material procurement: 5-10 days for fabric and components

- Production start: Cutting, sewing, assembly

- Customization: Printing, embroidery, hardware attachment

- Quality control: In-line inspection during production

- Packaging: Individual bags, master cartons

Communication During Production

- Request production photos at key stages

- Ask for first-off-line samples before full production

- Confirm any specification questions immediately

- Establish single point of contact for efficient communication

Step 6: Quality Inspection Before Shipping

Pre-shipment inspection protects your investment:

Inspection Options

- Supplier inspection: Factory QC team (included in standard process)

- Third-party inspection: SGS, Bureau Veritas, TUV ($200-$400 per inspection)

- Personal inspection: Your team visits factory

AQL Sampling Standard

Acceptable Quality Level (AQL) is the industry standard for sampling inspection:

- AQL 2.5: Standard for general consumer products

- AQL 1.5: Stricter standard for premium products

- Sample size: Based on order quantity (e.g., 80 samples from 1,000 units)

What Inspectors Check

- Quantity verification against order

- Visual defects (stains, tears, loose threads)

- Measurements against specifications

- Color consistency (Pantone matching)

- Function testing (zippers, snaps, handles)

- Packaging and labeling accuracy

Step 7: Shipping and Logistics

Shipping decisions impact cost and timeline significantly:

Shipping Method Comparison

| Method | Transit Time | Cost (China to US) | Best For |

|---|---|---|---|

| Ocean (FCL) | 20-30 days | $0.10-$0.30/unit | Large orders (5,000+ units) |

| Ocean (LCL) | 25-35 days | $0.30-$0.60/unit | Medium orders (1,000-5,000 units) |

| Air Freight | 7-10 days | $1.50-$4.00/unit | Rush orders, samples |

| Express | 3-5 days | $3.00-$8.00/unit | Small urgent shipments |

Shipping Terms (Incoterms)

- FOB (Free On Board): Supplier delivers to port; buyer handles ocean freight

- CIF (Cost, Insurance, Freight): Supplier handles freight to destination port

- DDP (Delivered Duty Paid): Supplier handles everything to your door

Step 8: Receiving and Verification

Final steps upon receiving your order:

Receiving Checklist

- Count cartons against packing list

- Check for shipping damage before signing

- Random sample inspection from multiple cartons

- Verify quantities match order

- Document any issues with photos immediately

Issue Resolution

- Minor defects: Negotiate credit or discount on next order

- Major defects: Return for replacement (terms per contract)

- Shipping damage: File carrier claim within timeframe

Timeline Expectations: Inquiry to Delivery

| Phase | Duration | Cumulative |

|---|---|---|

| Requirements + Research | 1-2 weeks | Week 2 |

| Sample Request + Evaluation | 2-3 weeks | Week 5 |

| Negotiation + Order | 1-2 weeks | Week 7 |

| Production | 4-5 weeks | Week 12 |

| Shipping (Ocean) | 3-4 weeks | Week 16 |

Planning recommendation: For seasonal products, start the buying process 16-20 weeks before needed in-stock date.

Cost Breakdown: What Goes Into Pricing

Understanding cost components helps evaluate quotes:

- Materials (30-40%): Fabric, hardware, thread, lining

- Labor (20-30%): Cutting, sewing, finishing, inspection

- Overhead (10-15%): Factory costs, equipment, utilities

- Margin (10-20%): Supplier profit

- Customization (5-15%): Printing, embroidery, special features

Landed Cost Calculation

FOB price is just the starting point. Plan total landed cost:

- FOB price per unit

- + Freight cost per unit

- + Customs duty (varies by product and country)

- + Import processing fees

- + Domestic delivery to warehouse

- = Landed cost per unit

Rule of thumb: Landed cost typically runs 20-35% above FOB price for ocean freight to US/EU.

Common Buying Mistakes and How to Avoid Them

Choosing Lowest Price Without Quality Verification

Problem: Extremely low quotes often indicate quality shortcuts.

Solution: Always evaluate samples before committing. Compare samples from multiple suppliers.

Underestimating Timeline

Problem: Assuming goods arrive faster than realistic.

Solution: Plan for 12-16 weeks minimum. Build buffer for unexpected delays.

Unclear Specifications

Problem: Vague requirements lead to production that doesn't match expectations.

Solution: Document every detail in writing. Reference approved samples in contracts.

Skipping Pre-Shipment Inspection

Problem: Discovering defects after goods arrive limits options.

Solution: Always inspect before shipping, especially for first orders with new suppliers.

Ignoring Communication Quality

Problem: Suppliers who communicate poorly during sales phase will communicate worse during problems.

Solution: Evaluate responsiveness and clarity as selection criteria.

Frequently Asked Questions

Direct manufacturers typically require 500-2,000 units for custom orders. Stock designs may be available at 100-300 units. Trading companies and distributors offer lower MOQs at higher per-unit cost.

Yes, reputable manufacturers welcome factory visits. Many buyers schedule visits around the Canton Fair (April and October) to meet multiple suppliers efficiently.

Address concerns with documentation (photos, inspection reports). Most suppliers will negotiate resolution—replacement, credit, or refund—based on contract terms and relationship value.

T/T (telegraphic transfer/wire transfer) is most common. PayPal works for samples. Letters of Credit provide protection for large orders but involve bank fees.

Agents add cost (5-10% of order value) but provide value for first-time buyers unfamiliar with import processes. As you gain experience, direct manufacturer relationships typically offer better value.

Conclusion

Successful beach bag buying requires systematic planning, thorough supplier evaluation, and clear communication throughout the process. The investment in proper process—especially sample evaluation and pre-shipment inspection—prevents problems that are expensive to fix after goods arrive.

Build relationships gradually. Start with smaller orders to verify supplier capability before committing to large volumes. Document everything, maintain regular communication, and address issues promptly when they arise.

The 10-16 week timeline may seem long, but it reflects the reality of international manufacturing and shipping. Planning ahead ensures you have quality products when you need them.