Understanding beach bag wholesale pricing is essential for making informed purchasing decisions and negotiating effectively with suppliers. This guide breaks down the cost structures, pricing factors, and volume discounts that determine what you'll actually pay鈥攈elping you budget accurately and identify the best value for your requirements.

Pricing Quick Reference

Canvas beach bags: $2.50-12.00/unit

Straw beach bags: $3.00-18.00/unit

Mesh beach bags: $1.50-8.00/unit

Raffia beach bags: $5.00-25.00/unit

Neoprene beach bags: $6.00-20.00/unit

Volume discount: 15-25% at 5,000+ units

Key Factors That Determine Beach Bag Pricing

Beach bag wholesale prices aren't arbitrary鈥攖hey reflect real costs across the supply chain. Understanding these factors helps you evaluate quotes accurately and negotiate effectively.

Material Selection

Materials typically represent 40-55% of total cost. Natural materials (straw, raffia) cost more than synthetic alternatives. Premium canvas (16oz) costs nearly double standard weight (8oz).

Manufacturing Complexity

Labor accounts for 20-30% of cost. Handwoven products require significantly more labor than machine-sewn bags. Complex construction (multiple pockets, liners, closures) adds cost.

Order Quantity

Volume is the biggest controllable pricing factor. Moving from 500 to 5,000+ units can reduce per-unit cost by 15-25% through material efficiency and production line optimization.

Customization Level

Basic styles are cheapest. Each customization adds cost: printing ($0.15-1.50), embroidery ($0.50-3.00), custom hardware ($0.30-2.00), custom labels ($0.10-1.50).

Price Ranges by Material Type

Different materials have vastly different cost structures. Here's what to expect for each major beach bag material category:

| Material | Basic Range | Premium Range | Key Cost Drivers |

|---|---|---|---|

| Canvas | $2.50-6.00 | $6.00-12.00 | Fabric weight, handle type, printing |

| Straw | $3.00-8.00 | $8.00-18.00 | Weave density, handmade vs machine, liner |

| Raffia | $5.00-12.00 | $12.00-25.00 | Natural vs paper, weave complexity, hardware |

| Mesh | $1.50-4.00 | $4.00-8.00 | Mesh density, frame structure, closure |

| Neoprene | $6.00-12.00 | $12.00-20.00 | Thickness, waterproofing, zipper quality |

| Jute/Burlap | $2.00-5.00 | $5.00-10.00 | Weave quality, lamination, reinforcement |

Note on Price Ranges

These ranges assume FOB China pricing at MOQ levels (500-1,000 units). Actual prices vary based on specific designs, current material costs, and supplier relationships. Always request detailed quotes for accurate budgeting.

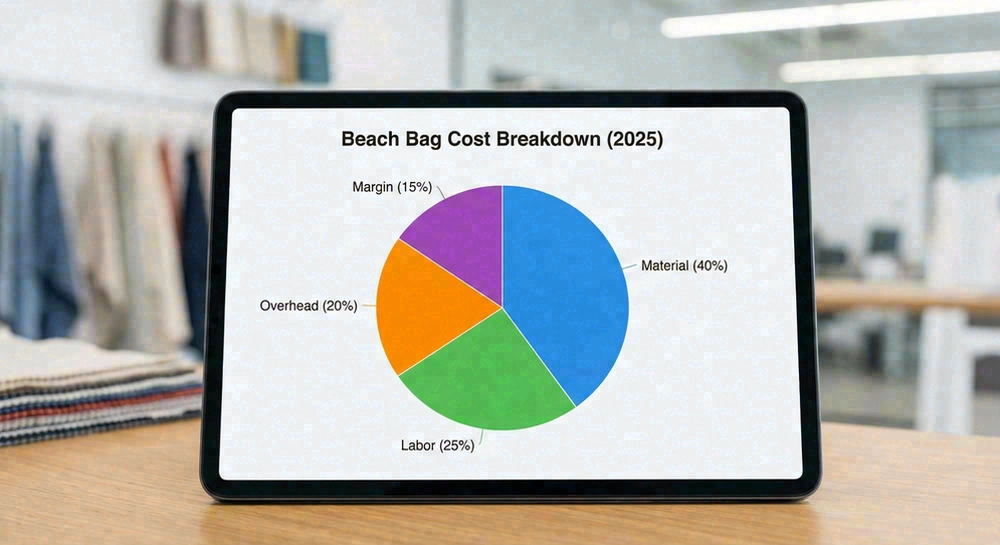

Manufacturing Cost Breakdown

Understanding where the money goes helps you identify opportunities for cost optimization:

40-55%

Materials

20-30%

Labor

10-15%

Overhead

10-20%

Margin

Example: Canvas Beach Tote Cost Breakdown

| Cost Component | Basic ($4.00) | Premium ($8.00) |

|---|---|---|

| Canvas fabric (body) | $0.80 | $1.60 |

| Handles/straps | $0.30 | $0.80 |

| Lining/pockets | $0.20 | $0.60 |

| Hardware/closures | $0.15 | $0.50 |

| Labor (cutting, sewing, QC) | $1.00 | $2.00 |

| Overhead (factory, utilities) | $0.55 | $1.00 |

| Packaging | $0.20 | $0.50 |

| Factory margin | $0.80 | $1.00 |

| TOTAL FOB PRICE | $4.00 | $8.00 |

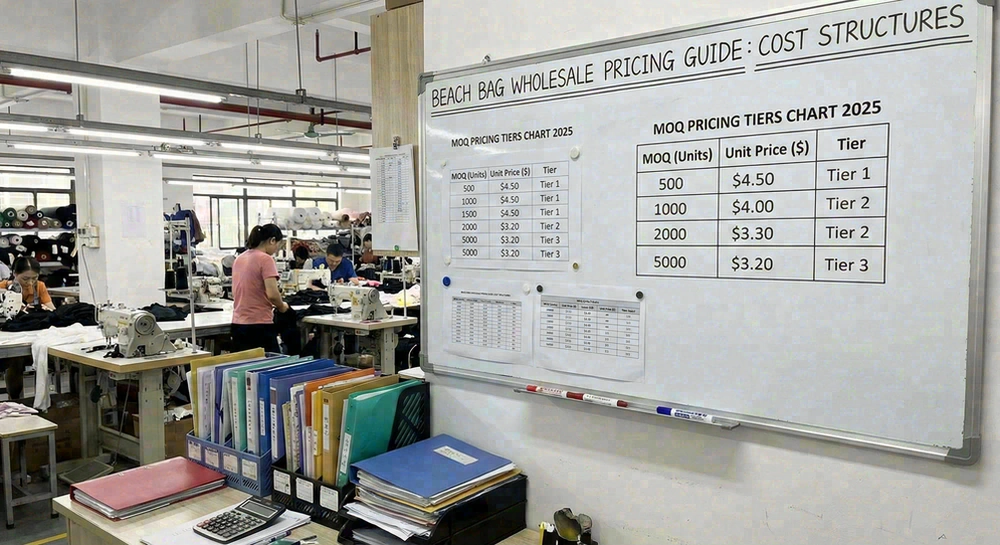

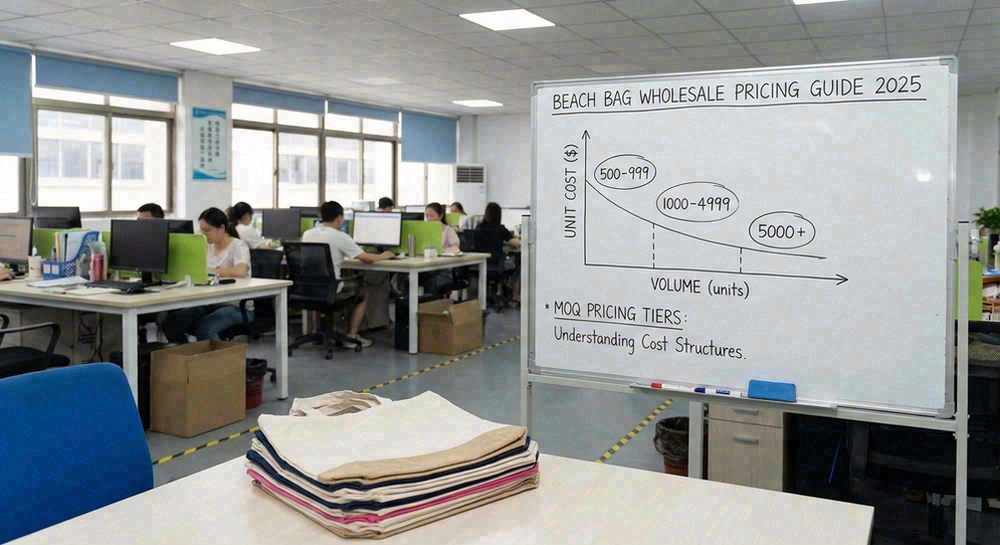

MOQ and Volume Pricing Tiers

Order quantity is the most significant factor you can control. Here's how volume affects pricing:

Customization Cost Add-Ons

Most quoted prices are for blank/basic products. Customization adds costs on top of base pricing:

Printing & Branding

| Decoration Type | Per-Unit Cost | Setup Fee |

|---|---|---|

| Screen print (1-2 colors, one side) | $0.15-0.50 | $30-80/color |

| Full-color digital print | $0.50-1.50 | $50-100 |

| Embroidery (small logo) | $0.50-1.00 | $50-150 |

| Embroidery (large design) | $1.00-3.00 | $100-200 |

| Woven label (brand tag) | $0.10-0.30 | $50-100 |

| Leather patch | $0.50-1.50 | $100-200 |

Hardware & Features

| Hardware Type | Per-Unit Cost | Notes |

|---|---|---|

| Standard zipper | $0.30-0.80 | Nylon coil, basic pull |

| YKK or branded zipper | $0.80-2.00 | Premium brand recognition |

| Metal hardware (D-rings, clasps) | $0.50-2.00 | Alloy vs brass vs stainless |

| Custom molded zipper pull | $0.20-0.50 | + $500-1500 mold fee |

| Magnetic snap closure | $0.30-0.80 | Standard vs heavy-duty |

Shipping and Logistics Costs

The quoted FOB price is just the beginning. Understanding shipping terms and costs is essential for accurate landed cost calculation.

FOB (Free on Board)

Price includes goods loaded at origin port. Buyer arranges and pays shipping.

Best for: Experienced importers with freight forwarder relationships

CIF (Cost, Insurance, Freight)

Seller covers freight and insurance to destination port. Adds $0.30-1.00/unit.

Best for: Buyers wanting simpler cost comparison

DDP (Delivered Duty Paid)

All-inclusive to your door including duties and customs. Adds $0.80-2.00/unit.

Best for: New importers wanting predictable total cost

Air vs. Ocean Freight

| Shipping Method | Cost/Unit | Transit Time | Best For |

|---|---|---|---|

| Ocean (FCL) | $0.20-0.50 | 4-6 weeks | Standard orders, cost priority |

| Ocean (LCL) | $0.40-0.80 | 5-7 weeks | Smaller orders, not full container |

| Air Freight | $2.00-5.00 | 7-10 days | Rush orders, samples, high-value items |

| Express (DHL/FedEx) | $5.00-10.00 | 3-5 days | Urgent samples, small quantities |

Hidden Costs to Watch For

Many first-time buyers are surprised by costs that weren't in the initial quote. Budget for these:

Sample & Development Fees

$50-300 per design for custom samples. Often refundable against bulk order, but not always.

Quality Inspection

$200-500 per shipment for third-party inspection (highly recommended). Some factories include basic QC.

Import Duties

Varies by country and product. US duties on beach bags typically 3-20% depending on material classification.

Customs Clearance

$100-300 per shipment for customs broker fees if not using DDP terms.

Inland Freight

Cost from port to your warehouse. Varies by distance and carrier. Often overlooked in budgeting.

Bank Fees

International wire transfer fees ($15-50 per transaction), L/C fees if applicable.

How to Negotiate Better Pricing

- Commit to annual volume forecasts: Even if you can't place a single large order, committing to annual volume (e.g., "We plan to order 10,000 units across 2025") often unlocks better per-unit pricing.

- Pay faster for discounts: T/T in advance payment (vs. L/C or split payment) typically earns 2-5% discount. The supplier's cash flow improves, and they pass some savings to you.

- Consolidate SKUs: Fewer styles in larger quantities per style is more efficient than many styles in small quantities. Consolidation reduces setup time and material waste.

- Order during off-peak season: September through January is typically quieter for beach bag manufacturers. Factories may offer capacity discounts to fill production lines.

- Build long-term relationships: Suppliers reward loyal customers with better pricing, priority scheduling, and more flexibility. Constantly switching suppliers costs you in subtle ways.

- Be flexible on specifications: Standard hardware, common materials, and simpler designs cost less. Ask what specifications could be adjusted to reduce cost without affecting quality.

Frequently Asked Questions

Wholesale prices range from $1.50 for basic mesh bags to $25+ for premium raffia styles. The most common range for mid-quality canvas and straw beach bags is $3-8 per unit at standard MOQ levels (500-1000 units).

Higher volumes drive lower per-unit costs through material efficiency, production line optimization, and reduced setup time per unit. Expect 5-10% savings at 1,000+ units, 10-15% at 3,000+, and 15-25% at 5,000+ units compared to base MOQ pricing.

Always clarify what's included. FOB prices typically include manufacturing, packaging, and loading at origin port. They usually exclude: international shipping, customs duties, inland freight, insurance, quality inspection, and any setup fees for customization.

Policies vary. Many manufacturers refund sample costs against the first bulk order, but this should be confirmed upfront. Some charge non-refundable development fees for complex custom designs. Sample shipping is almost never refundable.

Landed cost = FOB price + shipping + insurance + customs duty + customs clearance + inland freight + bank fees. For rough estimates, add 30-50% to FOB price for ocean freight to US/EU, or 60-100% for air freight. Get exact shipping quotes for accurate budgeting.

We believe in straightforward, transparent pricing. Request a detailed quote and we'll break down exactly what you're paying for鈥攏o hidden fees, no surprises.

- + Itemized quotes showing material, labor, and customization costs

- + Clear shipping options with cost comparison

- + Volume discount tiers clearly stated upfront

- + Sample costs refundable against bulk orders

Conclusion

Beach bag wholesale pricing reflects real costs across materials, manufacturing, customization, and logistics. Understanding these cost structures helps you evaluate quotes accurately, negotiate effectively, and budget realistically.

Key takeaways:

- Material matters most: Material selection drives 40-55% of total cost

- Volume is king: Moving from MOQ to 5,000+ units saves 15-25%

- Budget beyond FOB: Factor in shipping, duties, and hidden costs

- Relationships pay off: Long-term partnerships unlock better pricing

With this knowledge, you're equipped to make informed purchasing decisions and get the best value for your beach bag sourcing needs.