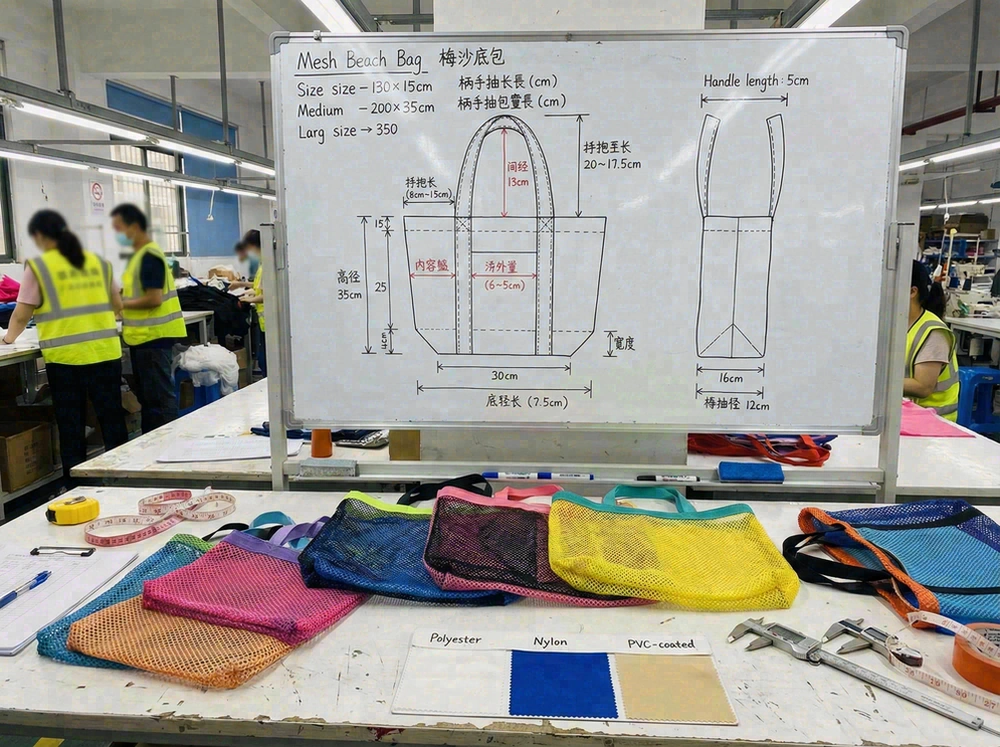

Mesh Beach Bags

Wholesale & Custom Manufacturing

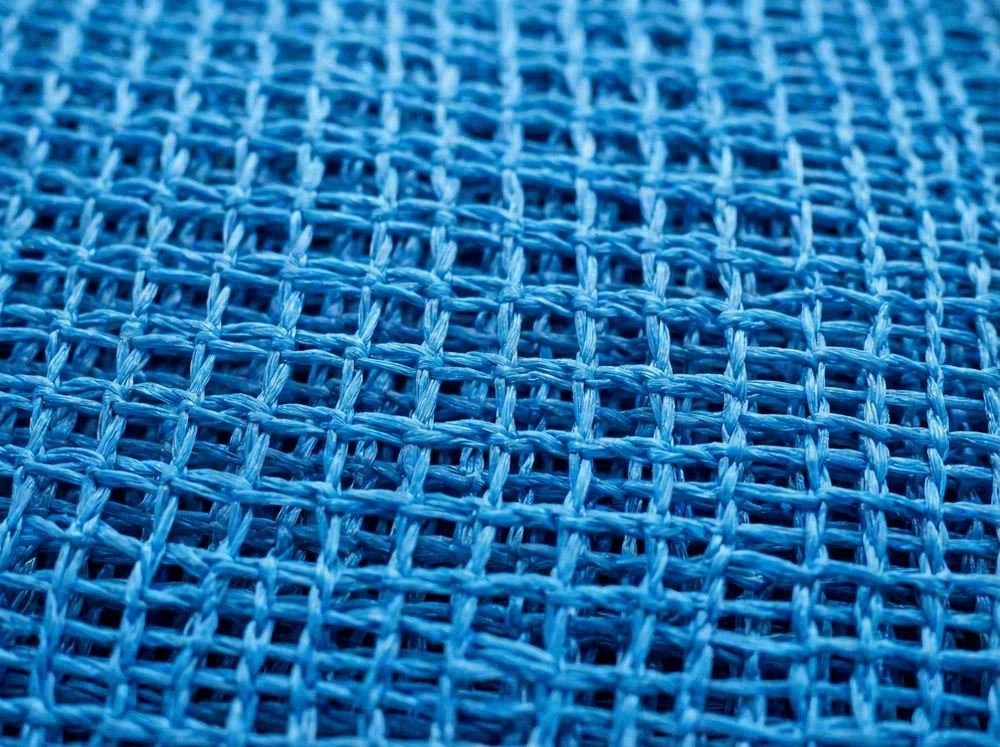

Source your next mesh beach bag line from a direct manufacturer built for promotional and retail orders. Breathable, sand-free mesh lets sand and water fall through, while reinforced handles and optional pockets keep the bag practical for repeat use. Choose classic mesh beach tote silhouettes, oversized carryalls, or zipper-top styles, then add your logo with print, heat transfer, or sewn labels.