Certifications & Quality Assurance: Beach Bag Quality Certification

For international buyers, "certified" only matters when it matches the material, market, and use case. Clanbag builds a documentation-ready quality system so your order can meet beach bag quality certification requirements with clear evidence - from AZO-free and phthalate-free material options to AQL-based inspections and shipment-ready reports. Our team supports OEM/ODM projects across mesh, canvas, straw, and mixed-material beach bags, aligning specs, labeling, and testing to your destination rules. If you need third-party verification, we can coordinate testing with accredited labs and share reports under NDA.

Material safety options

AZO-free dyes, restricted-substance controls, and declarations aligned to your target market and material set.

Process-based quality assurance

Incoming checks, in-line controls, and final inspections with sampling plans that match buyer standards.

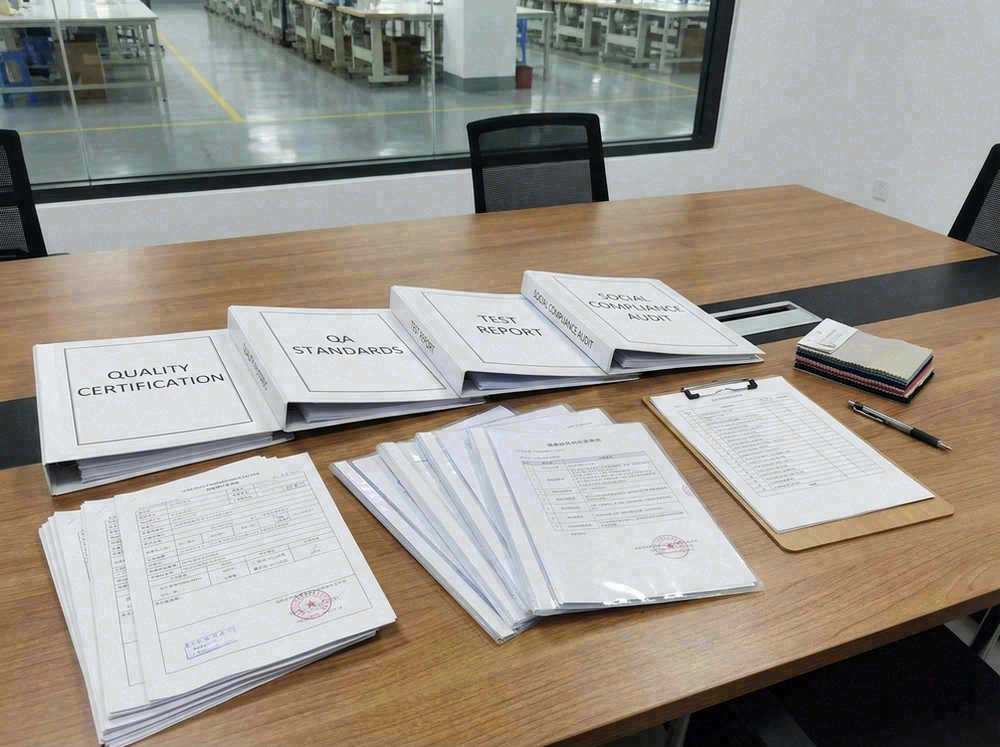

Documentation you can use

Document packs mapped to the exact SKU and production batch for retail onboarding and import clearance.