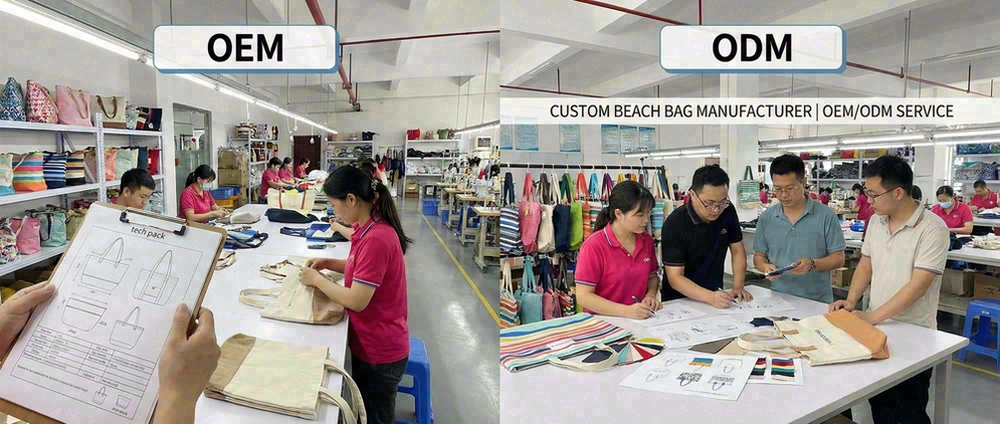

OEM/ODM Service:

Custom Beach Bag Manufacturing

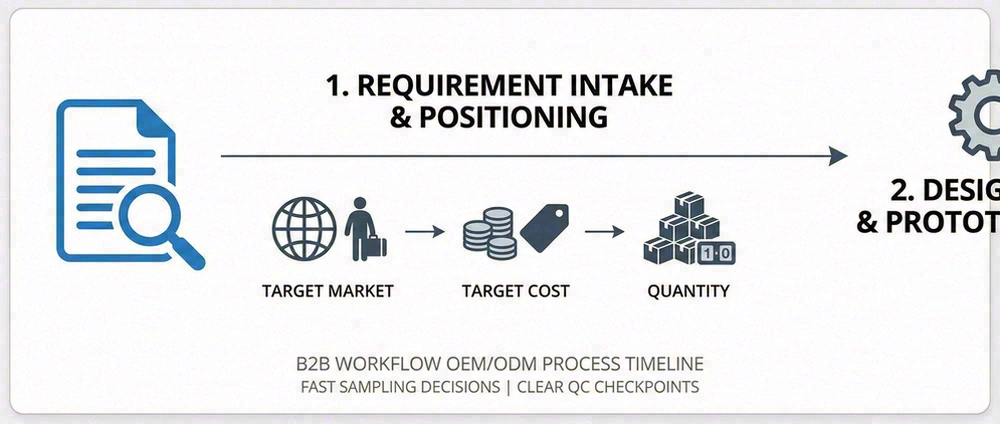

Looking for a custom beach bag manufacturer that can handle both OEM and ODM projects? Clanbag supports brand owners, resort retailers, and promotional buyers with a design-to-delivery beach bag OEM service, from concept sketches and material sourcing to sampling, mass production, and export packaging.

Full customization

Materials, size, pockets, closures, and packaging aligned to your target cost and retail positioning.

Faster decisions

Clear milestones for artwork, sampling, approvals, and production so timelines stay predictable.

Brand-ready output

Labeling, hangtags, carton marks, and barcodes supported for wholesale and retail programs.