Factory Tour: Inside Clanbag's Beach Bag Manufacturing

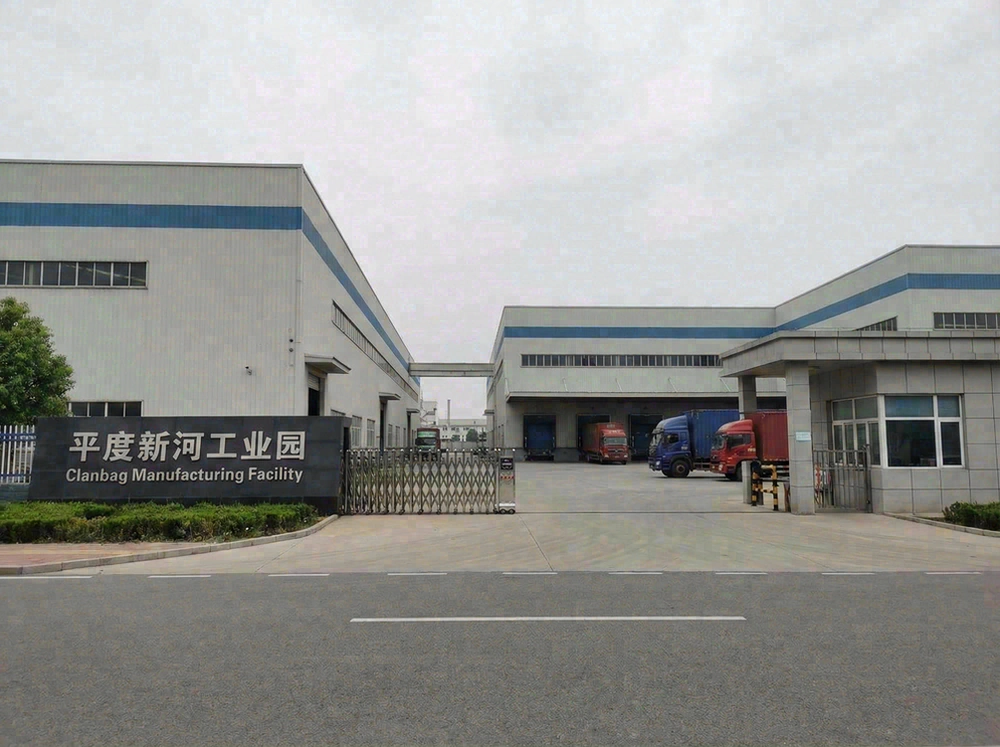

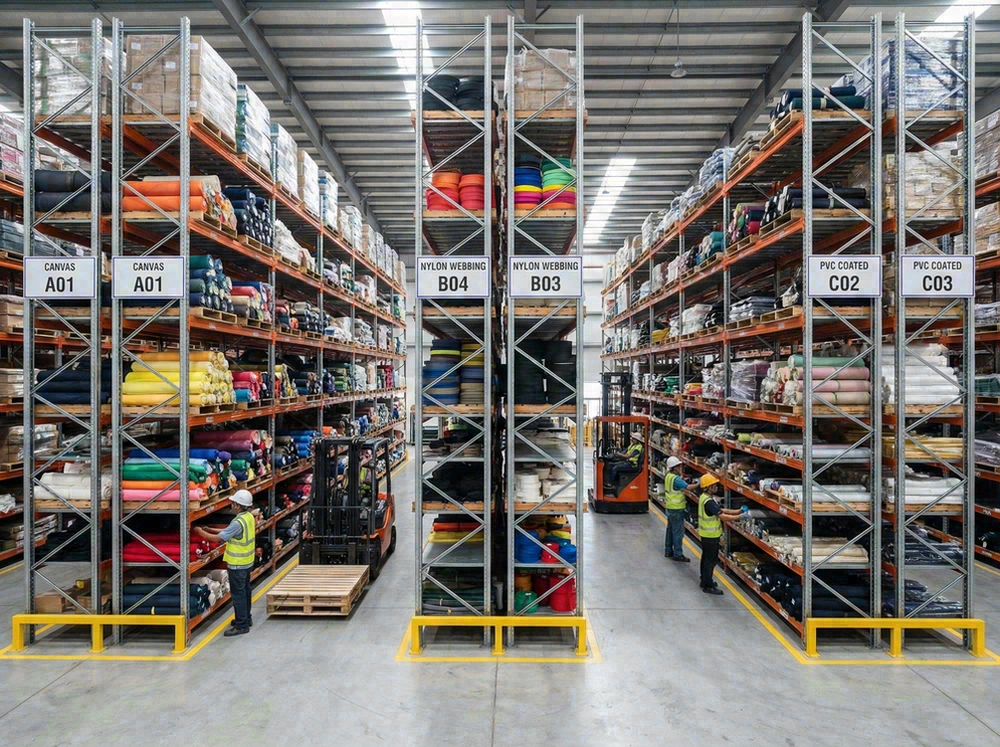

Overseas sourcing works best when you can verify the factory behind the quote. This page gives you a transparent look at our beach bag factory china - the production lines, quality checkpoints, and packing flow that support export orders. You will see how raw materials enter our Pingdu, Shandong bag manufacturing facility, how cutting and sewing teams build each style, and how QC confirms dimensions, stitching, and hardware before cartons are sealed.

Real workflow, buyer-focused

Follow the order path from incoming inspection to final packing so you can evaluate consistency, cleanliness, and process control.

QC you can audit

See checkpoints, defect handling, and inspection documentation practices designed for B2B accountability.

Export-ready packing

Review labeling, carton marking, and pre-shipment proofing options for wholesale and retail programs.