Canvas Beach Bags

Wholesale & Custom Manufacturing

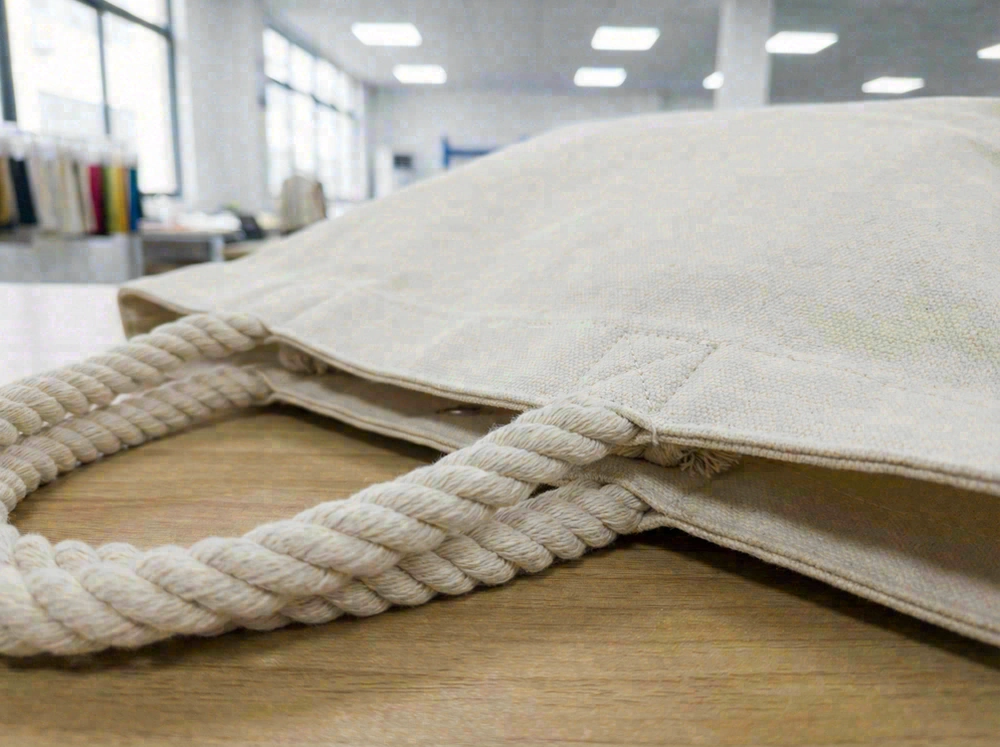

Clanbag manufactures canvas beach bags for wholesale programs, retail brands, resorts, and promotional distributors. Select 8oz, 12oz, or 16oz canvas and pair it with the right construction details: reinforced handles, gussets for extra capacity, and closure options from open top to zipper.

Choose the right canvas weight

8oz for lightweight promos, 12oz for everyday retail, and 16oz for premium and heavy carry.

Branding that stays sharp

Logo printing, labels, hangtags, and packaging specs matched to your sales channel.

Reinforced for real-world use

Handle attachment and seam reinforcement options designed to reduce returns and complaints.