Waterproof Beach Bags Wholesale & Custom Manufacturing

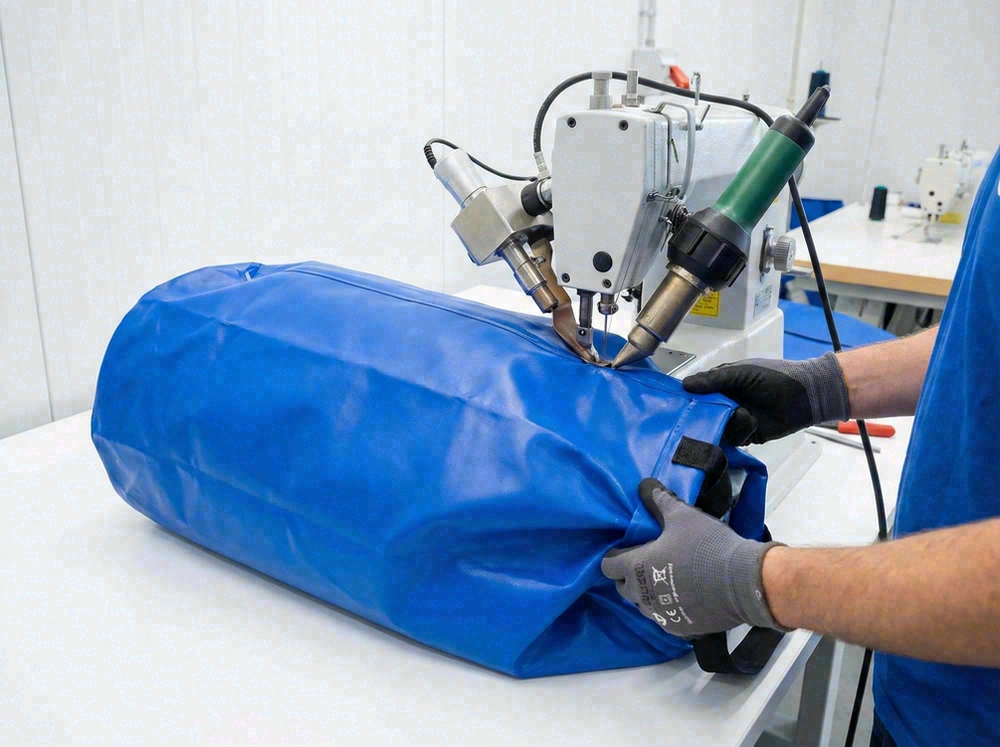

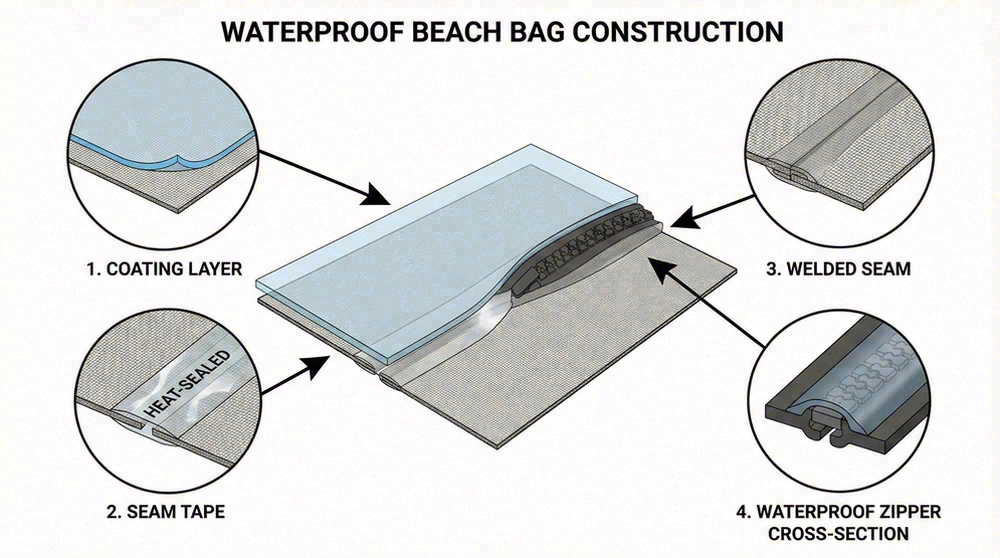

Clanbag manufactures waterproof beach bag programs for B2B buyers who need dependable water protection and premium shelf appeal. Choose PVC tarpaulin with welded seams for dry-bag performance, TPU laminated fabrics for a softer premium feel, or coated canvas for a classic tote look. We can build anything from a splash-proof water resistant beach bag to a fully sealed style with waterproof zippers and taped seams.

Multiple waterproof builds

Coating, lamination, seam tape, or welded construction

Material options that sell

PVC, TPU, coated canvas for beach and boat

Brandable and retail-ready

Custom logo methods and packaging options